Predictive Quality Using Artificial Intelligence for Achieving Excellence in Manufacturing

1. Quality Inspection for Excellence in Manufacturing

Quality inspection and, more specifically, production with zero defects have been explored in recent years, both from academia and industry. Even the increase in the quality of European products is aligned with Europe’s desire to create a European industry focused on delivering high-quality products and sustainability by reducing waste, improving the consumer experience, and developing economically viable businesses [1]. Hence, companies must use new technologies to implement this in their production environments. Recent developments in Information and Communication Technologies and Computer Science have explored approaches based on machine learning models to improve the production process for the most varied purposes [2]. Regarding quality inspection, it is possible to verify that several studies have been proposed in various industrial sectors, such as semiconductors [3], wheel-rim molding [4], or even injection molding [5]. However, these approaches usually require highly specialized labor for designing the machine learning models and preparing an integrated solution in the factory. Moreover, with the new developments aligned with Industry 5.0[6], aligning these approaches with the needs and requirements also defined by the human (operators, engineers, product designers, etc.) is imperative.

Currently, most of the solutions presented for quality inspection that uses Artificial Intelligence (AI) classify products as OK or NOK or identify the type of defect the product has, doing it autonomously and without human intervention. It is still possible to find approaches in which the system tries to predict possible defects before they occur, considering the process parameters and their evaluation over time.

2. Artificial Intelligence for Predictive Quality

There are several approaches to detecting defects in production. However, traditional methods tend to analyze the product and the process from the standpoint of detecting defects as soon as they occur rather than trying to predict and prevent them from occurring. With the emergence of AI, it was possible to start predicting system behavior by considering historical process information, as with production defect detection. In the case of industrial processes, it is possible to use AI to predict the emergence of production defects by monitoring the parameters that can be extracted from the process (velocities, temperatures, forces, etc.). In this way, by making AI models capable of perceiving whether different combinations of parameters may result in production defects, it is possible to alert and stop production before it occurs under these conditions, thus moving to quality prediction.

To implement this approach, it is necessary to perform some steps before creating the machine learning model and deploying it to be used in production.

2.1. Data Collection

This phase aims to ensure that methodologies and solutions are developed to extract the necessary data from the process and the product. In other words, this first phase focuses on integrating software and the different machines to send the execution data to an environment where this data can be stored and later analyzed. In this phase, it is necessary to see which communication protocols will be used to extract the data, such as OPC-UA [7], which has been gaining increasing traction in the industrial environment, facilitating data extraction.

In addition to data extraction, it is also necessary to ensure that this data is pre-processed and stored to be used later to create machine learning models. So, we move on to the next phase, which is pre-processing.

2.2. Pre-Processing

The data that appears in the raw format must be processed in such a way that this data can be useful for generating the knowledge and models we want. So, there is some pre-processing required to transform this unorganized data into something that can be useful. This process depends mainly on the machines we monitor and how they make the data available. We have cases where the data is already generated but is stored in files like text or CSV. In other cases, we have data generated continuously, which needs to be jobs stored in various entries that may make sense. Not only does the data need to be extracted, but it also needs to be harmonized and saved according to a known data model so that it can be recognized when used. This whole process of transforming raw data into data organized and saved in a known format is called pre-processing. After this process phase, we can move on to the steps closer to creating machine learning models.

An example of a dataset after pre-processing could be the following, shown in Table 1.

| Machine 1 | |||

| Parameter 1 | Parameter 2 | Parameter 3 | Parameter 4 |

| 2345 | 432 | 352 | 325 |

| 546 | 213 | 345 | 543 |

| 654 | 2143 | 324 | 453 |

2.3. Labeling

In the case of quality inspection, the objective in most cases is the creation of a classifier that will indicate whether the product will be defective or not when the process has a specific combination of parameters. To create these classifiers, it is then necessary to do the labeling of the data we have at our disposal (historical data). So, simplistically, the labeling process focuses on identifying, for each of the saved parameter combinations, the execution as OK or NOK (Not OK). The goal is to add more data to the dataset indicating whether the products were produced correctly or with defects for each run. It is also possible to make some variations to the labeling. For example, instead of just classifying as OK or NOK, classifying with different types or severity of defects. In this case, it would be something like OK, defect type 1, defect type 2, etc.

Using the example in Table 1, the dataset after labeling could look like this (Table 2). In the end, the goal is for our machine learning model to be able to predict the result of the last column, given as input the parameters (Parameter 1 to 4).

| Machine 1 | ||||

| Parameter 1 | Parameter 2 | Parameter 3 | Parameter 4 | OK/NOK |

| 2345 | 432 | 352 | 325 | OK |

| 546 | 213 | 345 | 543 | NOK |

| 654 | 2143 | 324 | 453 | OK |

There are several approaches to labeling, the most traditional and usually the manual labeling, which a person either done later by a developer or engineer or even by an operator during production, using additional software, such as a Smart MES, which allows the operator to enter whether a product has a defect or not. In addition to the more traditional approach, it is possible to use automatic or semi-automatic techniques.

2.4. Model Creation

After the previous steps, we can create our predictive models using machine learning algorithms. For the creation of the models, data is used to train the models, and data is used to test whether the models created have acceptable performance in the classifications. Thus, the dataset is divided into a training dataset (usually larger) and a test dataset (smaller). Usually, this division uses around 80% of the data for model training, and the remaining 20% is used for testing and validating the models.

Then, with the available dataset, the different machine learning algorithms are explored to create classifiers, each with its strengths that can have better or worse results depending on the available data. Some of these possible algorithms are Support Vector Machines, and Artificial Neural Networks, among others [8]. After selecting the candidate algorithms, models are created with the trained dataset and tested using the test dataset. If any model is satisfactory, it is then selected and used to generate the predictions. If none of the models are acceptable, other algorithms, or the same ones with different parameterizations, can be used to develop new models.

3. Smart MES as an Enabler

Smart Manufacturing Execution Systems (Smart MES) such as RAILES can play a crucial role in integrating and using these predictive quality approaches due to their data extraction, harmonization, storage, and the ability to interoperate with different data sources and software tools. In a way, a Smart MES like RAILES can play the central role that facilitates the integration of these features, which are usually difficult to integrate and maintain. In an ideal case, the Smart MES can even provide all these functionalities, from data extraction and storage to generating forecasts using predictive models embedded in the Smart MES itself, facilitating the solution’s development, integration, and maintenance.

4. Industrial Application

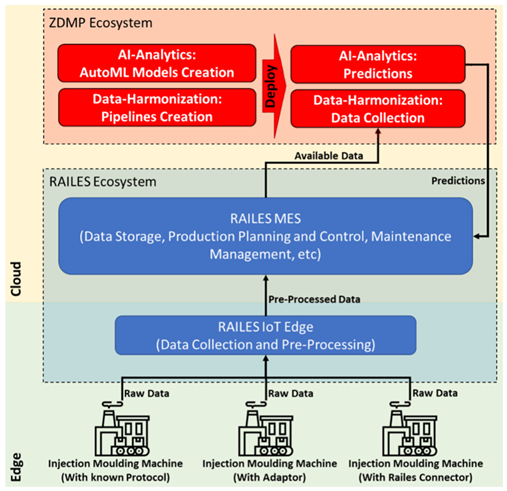

In the context of the European project RAIZED [9], Muvu, in partnership with Vipex, developed a predictive quality solution for plastic injection molding machines. Muvu used its Smart MES – RAILES for data collection, pre-processing, labeling, and integrating functionalities to create and deploy the predictive models offered by the ZDMP platform [10]. Fig. 1 shows the system’s general architecture used and tested for three machines.

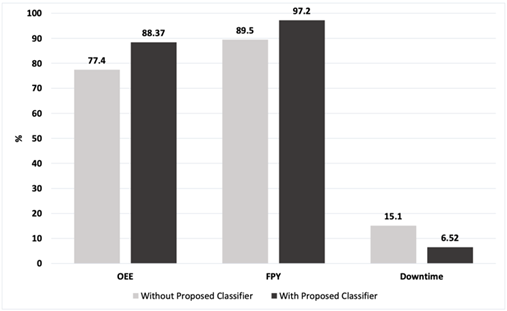

To evaluate the proposed solution’s performance, three Key Performance Indicators (KPIs), the Overall Equipment Effectiveness (OEE) [12], First Pass Yield (FPY), and Downtime. These KPIs were calculated before and after using the predictive quality solution. Fig. 2 shows the values of these KPIs before and after the solution, and it is possible to see an improvement in these KPIs.

5. Conclusions

As was presented before, zero-defect production is essential to guarantee excellence in manufacturing. Therefore, AI can play a vital role in achieving this goal. In this post, it was possible to see how the process of creating a predictive quality solution is designed and the required steps. Besides these steps, other actions may happen when problems are related to a lack of data or poor data quality. Some techniques, such as feature selection or data augmentation, can mitigate these problems.

References

[1] MADE IN EUROPE – The manufacturing partnership in Horizon Europe (https://ec.europa.eu/info/sites/default/files/research_and_innovation/funding/documents/ec_rtd_he-partnership-made-in-europe.pdf)

[2] Peres, R. S., Jia, X., Lee, J., Sun, K., Colombo, A. W., & Barata, J. (2020). Industrial Artificial Intelligence in Industry 4.0-Systematic Review, Challenges and Outlook. IEEE Access, 8, 220121-220139.

[3] Melhem, M., Ananou, B., Ouladsine, M., & Pinaton, J. (2016). Regression methods for predicting the product’s quality in the semiconductor manufacturing process. IFAC-PapersOnLine, 49(12), 83-88.

[4] Kabasakal, İ., Keskin, F. D., Koçak, A., & Soyuer, H. (2019, August). A Prediction Model for Fault Detection in Molding Process Based on Logistic Regression Technique. In Proceedings of the International Symposium for Production Research 2019 (pp. 351-360). Springer, Cham.

[5] Zhang, S., Dubay, R., & Charest, M. (2015). A principal component analysis model-based predictive controller for controlling part warpage in plastic injection molding. Expert Systems with Applications, 42(6), 2919-2927.

[6] European Commission, Directorate-General for Research and Innovation, Renda, A., Schwaag Serger, S., Tataj, D. (2022). Industry 5.0, a transformative vision for Europe : governing systemic transformations towards a sustainable industry, Publications Office of the European Union. https://data.europa.eu/doi/10.2777/17322

[7] https://muvu.tech/the-role-of-equipment-communication-and-standards/

[8] Lorena, A. C., Jacintho, L. F., Siqueira, M. F., De Giovanni, R., Lohmann, L. G., De Carvalho, A. C., & Yamamoto, M. (2011). Comparing machine learning classifiers in potential distribution modelling. Expert Systems with Applications, 38(5), 5268-5275.

[10] https://www.zdmp.eu/

[11] https://muvu.tech/how-to-calculate-oee/

[12] Silva, B., Marques, R., Faustino, D., Ilheu, P., Santos, T., Sousa, J., & Rocha, A. D. (2023). Enhance the Injection Molding Quality Prediction with Artificial Intelligence to Reach Zero-Defect Manufacturing. Processes, 11(1), 62.